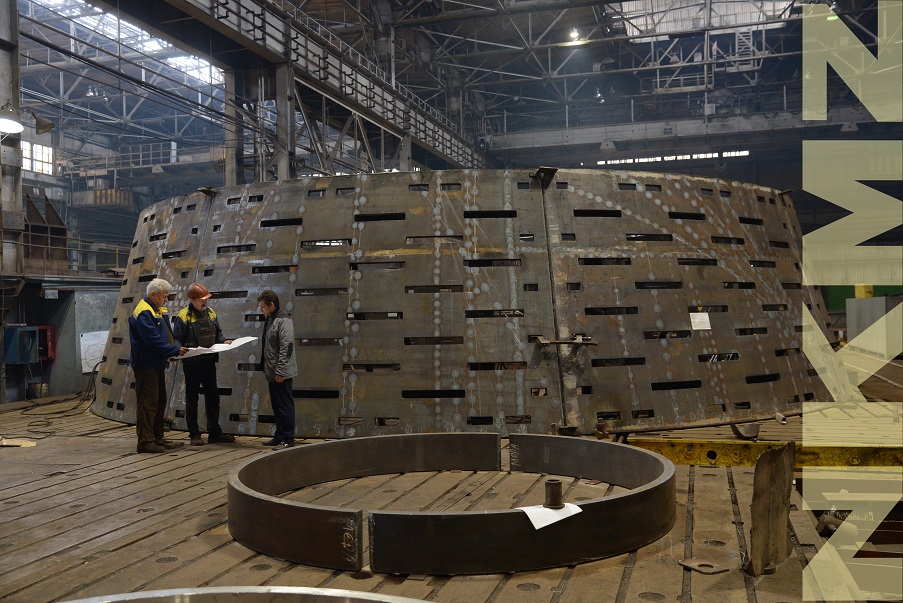

The next, third casing of the blast furnace is being manufactured today by NKMZ, using the unique technological capabilities of the equipment which is installed in the workshops of the enterprise.

The casing is the main supporting body of the blast furnace. It is lined with appropriate refractory materials that make it possible to smelt cast iron in it.

The casing, which the NKMZ workers are making today, is a massive and large-sized structure, consisting of four shells installed on top of each other – three conical and one cylindrical. Their diameter is 12-14 m, the total height of the casing is 9 m and the total weight is 160 tons.

In the manufacture of tapered shells, the first most difficult task is to ensure their rather strict geometric dimensions during the segments’ rolling process. So, with a finished part diameter of 12-14 m and a sheet thickness of 70 mm, an accuracy of up to 5 mm is required. This task is solved in workshop No. 16 thanks to the use of a unique Haeusler machine, which allows rolling large shells of great thickness with high accuracy. And then in the machining-assembling shop No. 8 on a high-precision up-to-date boring machine with CNC from the Skoda, the finishing machining of the rolled segments is carried out. Here, the most difficult operation is to machine the places for the installation of cooling beds.

Today, the first stage of manufacturing of the third casing has been completed: four shells have already been finished in workshop No. 16. Soon they will be disassembled into segments and passed for machining.

Press relations service of NKMZ