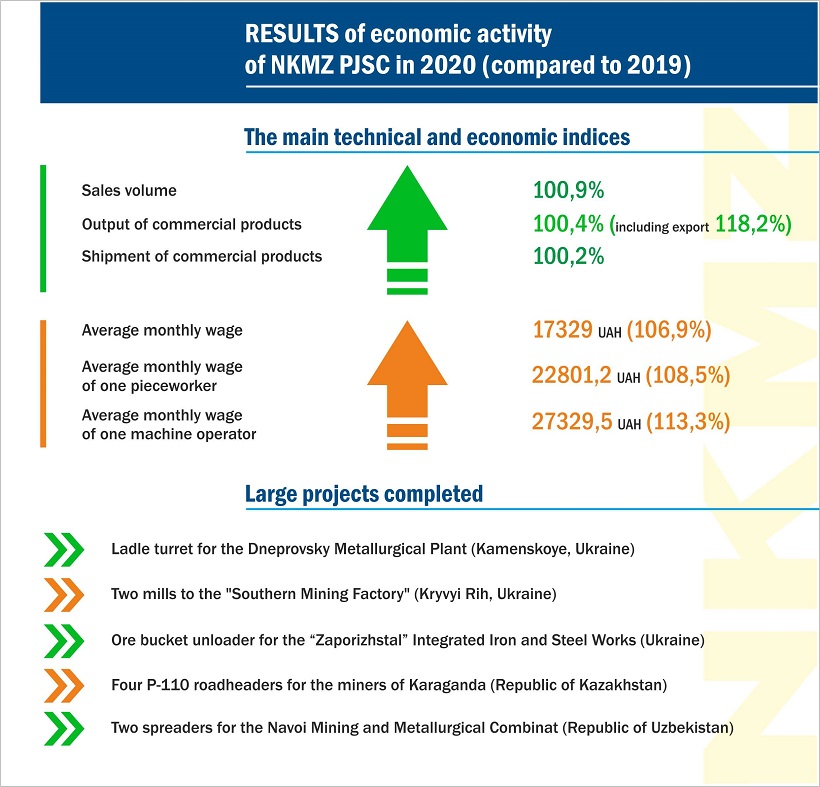

Novokramatorsky Mashinostroitelny Zavod (Kramatorsk, Donetsk region) has summed up the results of economic activity in 2020.

The main technical and economic indices reflect positive dynamics. Compared to 2019, the sales volume amounted to 100.9 %, the output of commercial products – 100.4 % (including for export – 118.2%), the shipment of commercial products – 100.2%.

The average monthly wage of NKMZ workers increased by 6.9% compared to 2019 and amounted to UAH 17,329. At the same time, the average monthly wage of one pieceworker increased by 8.5%, amounting to UAH 22801.2, one machine operator – by 13.3% to UAH 27329.5.

Among the largest orders completed by the enterprise in 2020 was a ladle turret for the Dneprovsky Metallurgical Plant (Kamenskoye, Ukraine), two mills to the “Southern Mining Factory” (Kryvyi Rih, Ukraine), a powerful ore bucket unloader for the “Zaporizhstal” Integrated Iron and Steel Works (Ukraine), four P-110 roadheaders for the miners of Karaganda (Republic of Kazakhstan), two spreaders for the Navoi Mining and Metallurgical Combinat (Republic of Uzbekistan).

Novokramatorsky Mashinostroitelny Zavod is a large machine-building enterprise with a closed production cycle, specializing in the production of rolling, metallurgical, press-forging, mining, hydraulic engineering, handling and special-purpose machinery.

Press-relates service of NKMZ