Cold rolling mills for aluminum and steel strips production are working nowadays at many ferrous and non-ferrous metallurgical works in CIS countries and abroad.

When designing the rolling mills a package of software on automated calculation, design and optimization both of technological schedules and structural parameters of future equipment are implemented.

At that a number of the following main actual tasks is being solved:

rolling mills fitting with hydraulic fast acting high-sensitive screw-down mechanisms as well as with high-efficient mechanisms of preliminary and prompt strip control;

optimization of reduction schedules and usage of high-efficient rolling lubricants;

development, research and mastering of the new rolling processes enabling intensification of technological schedules and the finished product quality improvement.

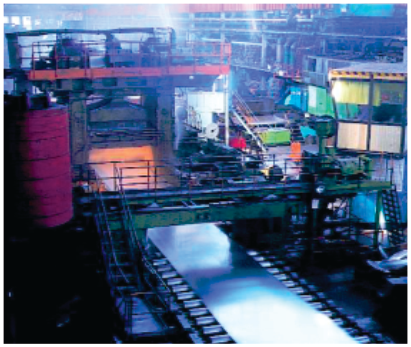

Aluminum Hot Rolling Mill