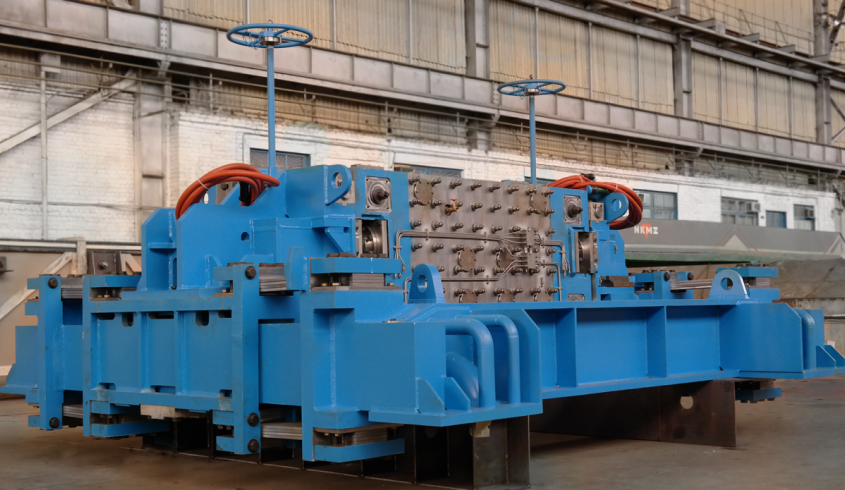

Application:

initial crystallization of liquid metal around the perimeter and the formation of an ingot of a given cross-section.

Design features:

One mould is used for all standard sizes of the ingot in width.

Automatic sealing of cooling water supplies when the mould is installed on the tilting mechanisms.

The drive for moving narrow walls is mechanical or hydraulic. Ability to adjust the width of the ingot, both when setting up the machine and during casting.

Ability to adjust the width of the ingot, both when setting up the machine and during casting.

The copper and base plates of the mould moving wall, as well as the narrow walls, are pressed against the base wall by a clamping device. The clamping force is provided by a pack of disc springs. The unclamping force is provided by hydraulic plunger cylinders;