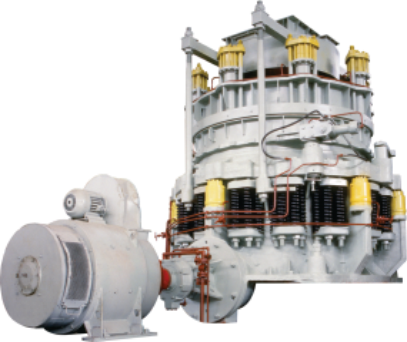

Cone crushers

Cone crushers are designed for fine crushing of the materials with the compression strength up to 300 Mpa.

Jaw crushers

Jaw crushers are designed for dry crushing of rocks with medium and high hardness and compression strength up to 300 Mpa.

Crushers of this type are stationary mounted to the foundation.

Crushers are fitted with device for control of discharging slot width.

Jaw crushers made by NKMZ have high reliability and long service life.

Crushers are easy in operation and maintenance.

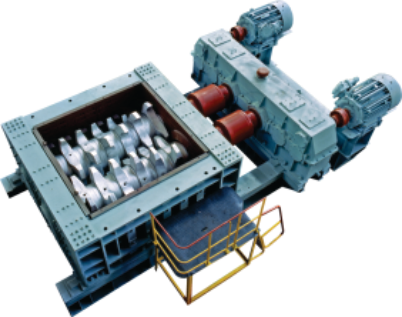

Auger-type toothed crushers

These crushers are designed to crush ores and lump materials with the compression strength up to 180 MPa

Crushers of this type are simple in design, small in size (low height) and easy in operation. They can be installed at the stationary, semi-stationary and mobile crushing stations.

Advantages:

Materials apt to sticking may be successfully processed;

Minimum capital outlays are required for erection of these machines and special vibration-proof foundations are not needed at all;

Crushers feature minimum specific metal content.

Hammer crushers

Hammer crushers are designed to crush coal of various ranks (prior to its coking), limestone, etc.

Crushers have high reliability and long service life.

Crushers are equipped with wear-resistant surface-hardened hammers.

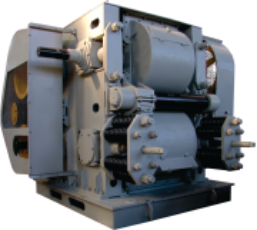

Four-roll crushers

Four-roll crushers are designed to crush coke or coal by squashing and partially by grinding them between the rolls.

A top pair of rolls provides primary crushing while the bottom rolls serve for final crushing due to smaller roll gap.

Double-roll crushers

Double-roll crushers are designed to crush manganese carbonate rocks, coal, limestone, marl, etc.

Provision of a safety device, enabling the uncrushed material pass through.

Rotary crushers

Rotary crushers are designed for primary crushing of coal and other mineral resources.