Purpose:

charging of dummy bar into mould;

discharging of dummy bar out of the mould;

ingot journey along the technological axis of CCM;

ingot rebend;

possibility to carry out “mild cobbing”.

Structural features:

Segments structure provides the following:

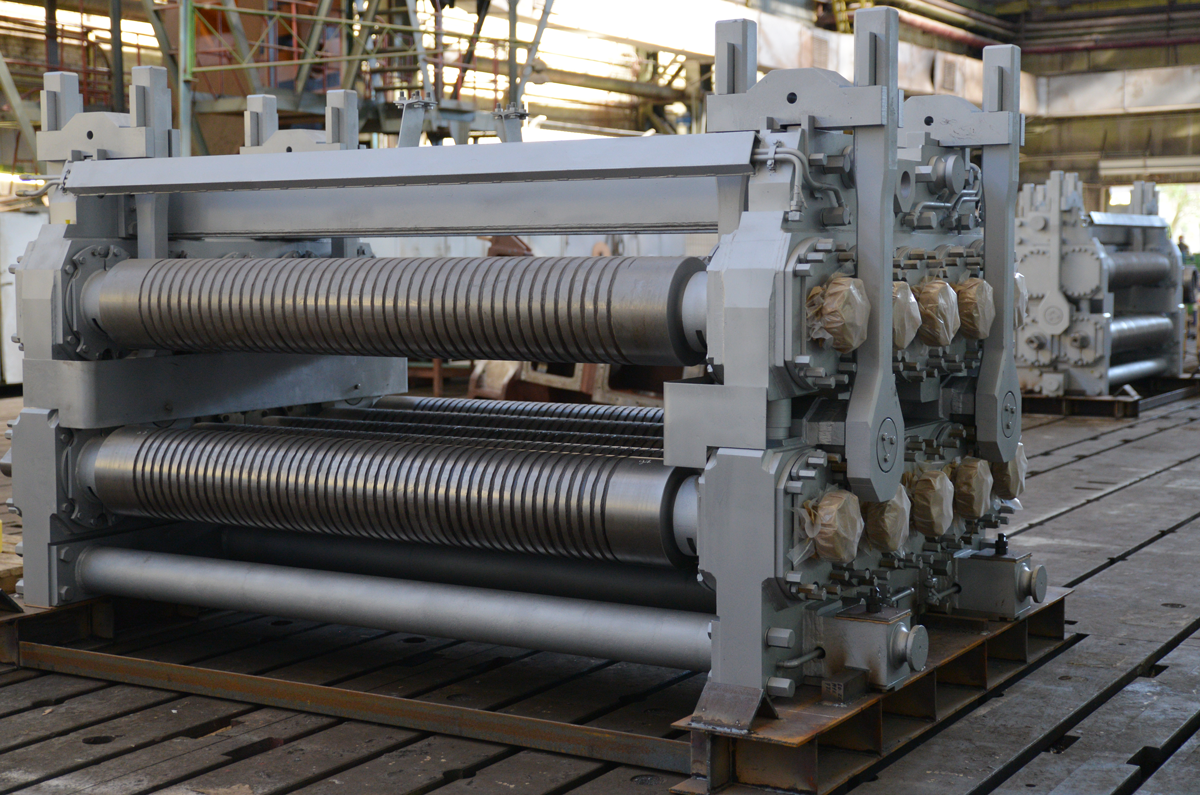

Precise following of technological axis within the segment;

Stability of technological process;

Compliance with ingot cooling mode;

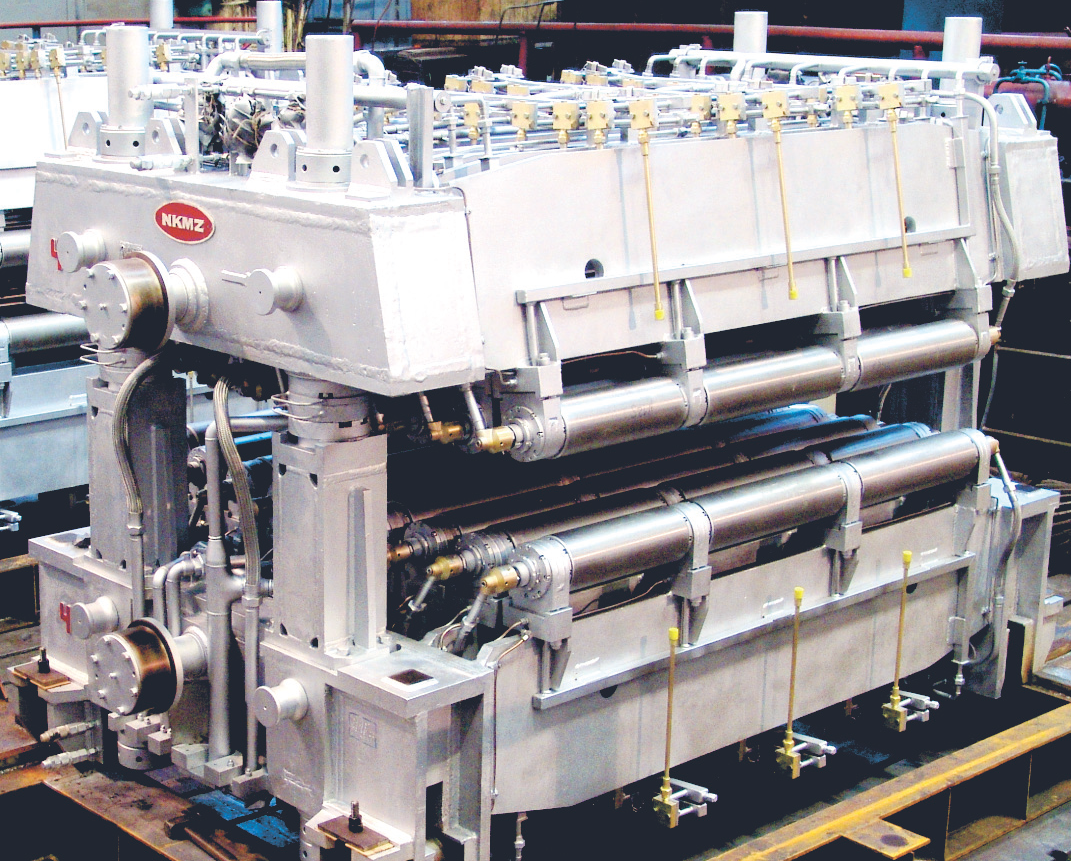

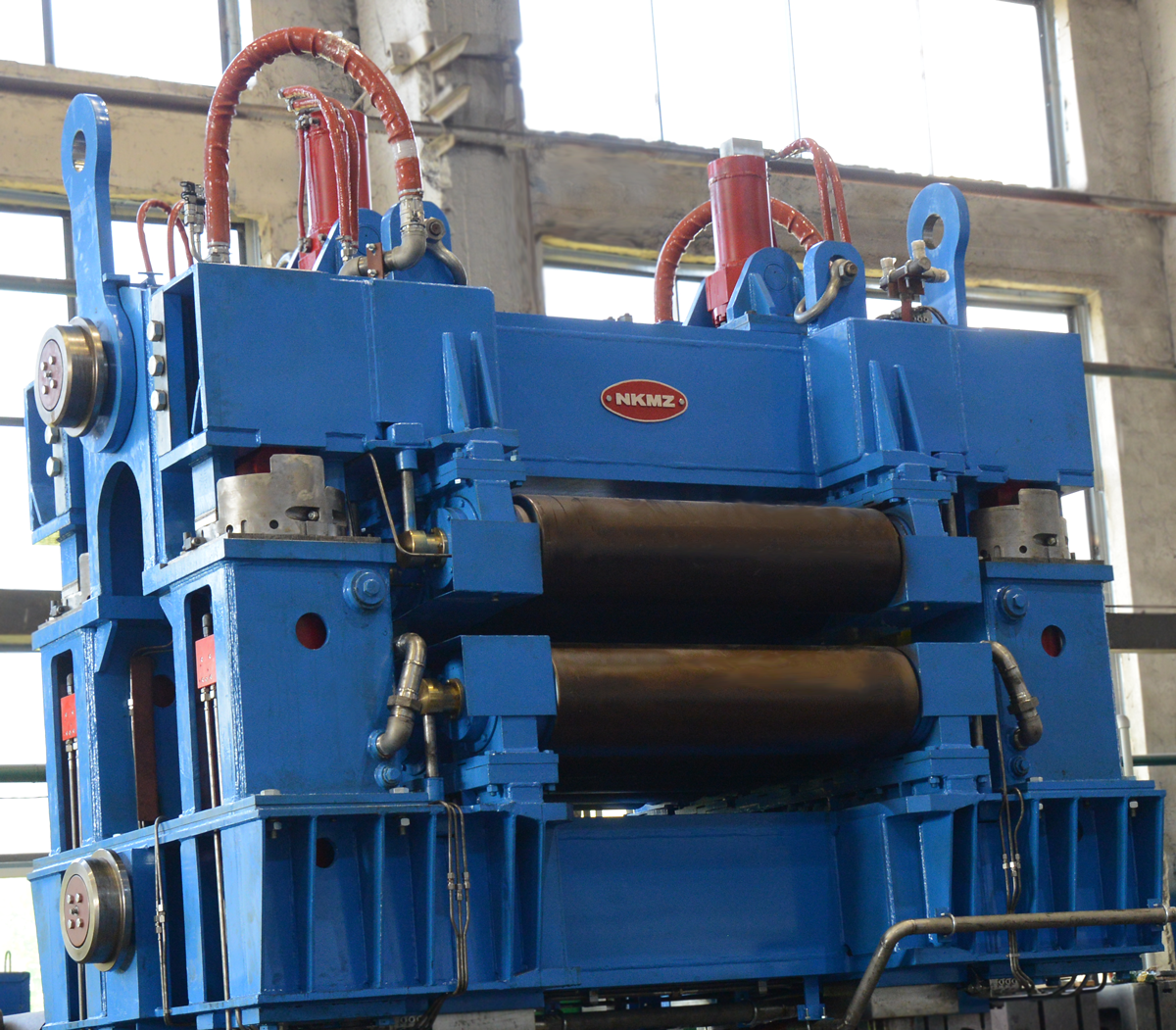

Bottom and top frames are made in form of firm welded structures out of sheet steel;

Frames are connected with each other by means of pillars with hydraulic cylinders;

Bottom and top frames serve as supports for driven and idle segments rollers;

Each top frames with rollers are driven by four hydraulic cylinders;

Hydraulic cylinders control blocks are located just on the segments and effectively protected against heat emission;

Rollers bearing assemblies are installed onto support platforms of the top and bottom frames;

The ingot is cooled by water-and-air mixture by means of special collectors with sprayers;

Mounting points structure provides quick segments change;

Precise rollers resistance per 1 mm diameter wear is provided by appliance of corresponding materials, manufacturing methods and efficient cooling.