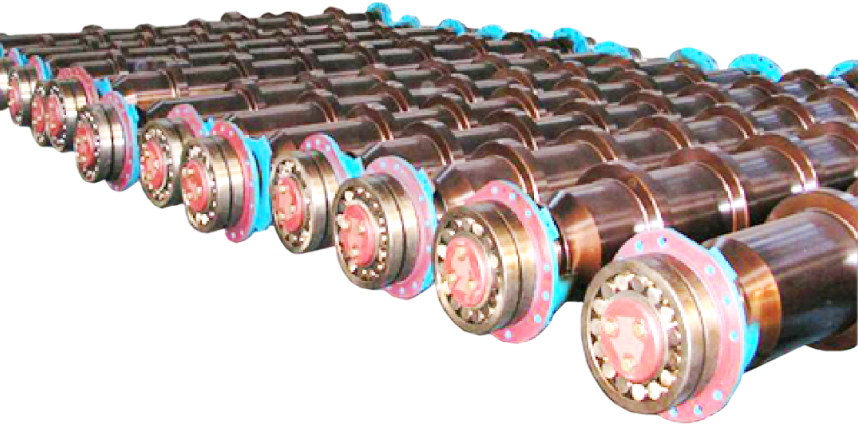

Engineering capabilities of NKMZ make it possible to manufacture both the roll tables themselves and spares to them in the form of some elements and units of rollers complete with bearing supports of various design and assembly.

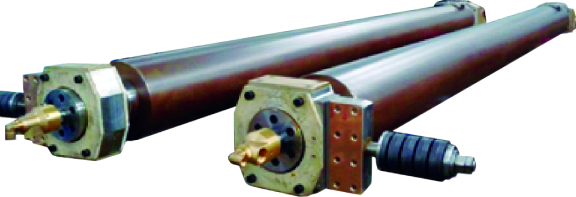

ROLLER TABLE ROLLERS

FORGED ROLLERS WITH CYLINDRICAL BODIES

Field of application:

Heavy-duty main mill tables, charging, receiving and trailer roll tables for breakdown, plate, wide-strip, billet and rail-and-structural steel mills.

Roller material:

Carbon, structural and high-alloy steels.

Design features:

Roller body and necks heat treatment, special heat- and wear-resistant coatings; if required and at the customer's request the bearing supports and roller body may be cooled.

Dimensions:

Body diameter = 150 - 500 mm; body length = 700 - 5000 mm. Roller weight: up to 8,0 t.

FORGED DISK ROLLERS

Field of application:

Trailer tables for plate and wide-strip mills.

Roller material:

Carbon, structural and high-alloy steels.

Design features:

Roller necks heat treatment.

Dimensions:

Body diameter = 200 - 750 mm; body length = 2000 - 3000 mm.

Dimensions:

Roller weight: up to 5,7 t.

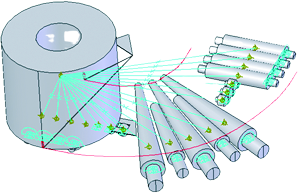

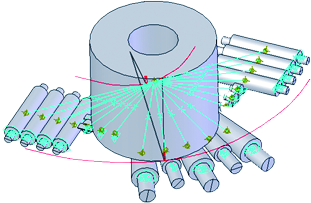

FORGED ROLLERS WITH CONICAL BODIES

Field of application:

Roll tables for turning workpieces around during rolling in plate and plate-by-plate reversing mills. Product transport lines.

Roller material:

Carbon, structural and high-alloy steels.

Design features:

Roller body and necks heat treatment.

Dimensions:

Body diameter = 250 - 600 mm; body length = 2500 - 7200 mm. Roller weight: up to 13,5 t.

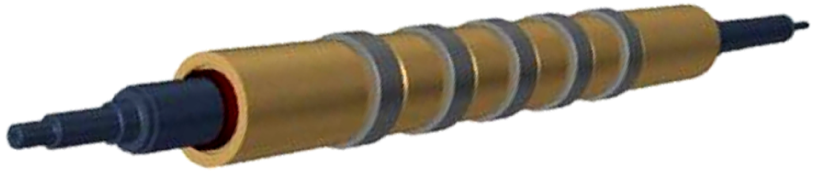

FORGED ROLLERS WITH BICONICAL BODIES

Field of application:

Roll tables for aluminium and aluminium alloys hot rolling mills.

Roller material:

Carbon, structural and high-alloy steels.

Design features:

tapered sections hardness: 60...70 HSD;

tapered sections hardened case depth – not less than 7 mm;

tapered sections roughness: Ra 0,8...1,6.

Dimensions:

Body diameter = 250 - 565 mm; body length = 1700 - 4500 mm. Roller weight: up to 10 t.

FORGED ROLLERS WITH FLANGES

Field of application:

Trailer tables for section and pipe-rolling mills.

Roller material:

Carbon, structural and high-alloy steels.

Design features:

Roller bodies and necks heat treatment, internal cooling of rollers, wear-resistant coating.

Dimensions:

Body diameter = 200 - 600 mm; body length = 400 - 1400 mm. Roller weight: up to 3,0 t.

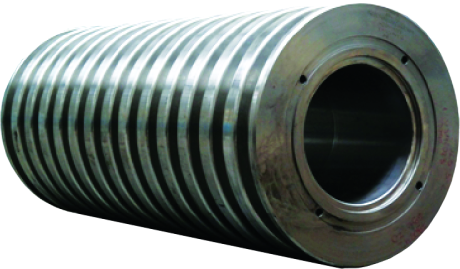

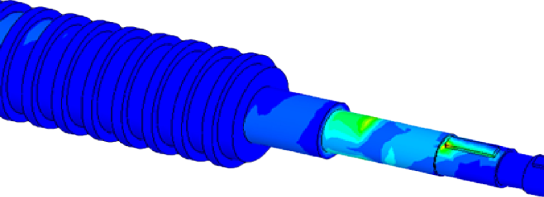

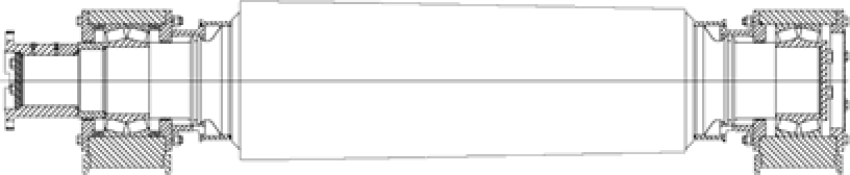

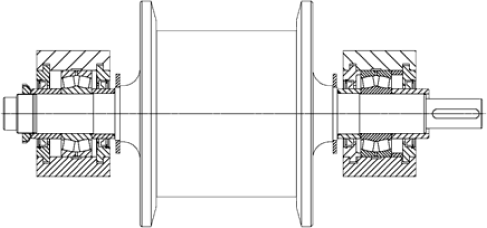

HIGH-SPEED ROLL TABLES WELDED ROLLERS

Field of application:

High-speed runout tables for wide-strip hot mills.

Roller body material:

Heat-resistant cast iron, wear-resistant stainless steels.

Design features:

Roller body internal cooling, static and dynamic balancing.

Dimensions:

Body diameter = 260 - 300 mm; body length = 1700 - 2500 mm. Roller weight: up to 0,6 t.

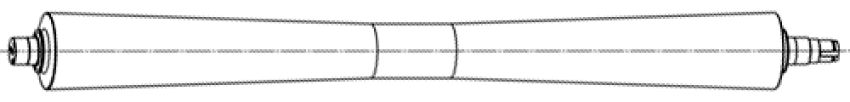

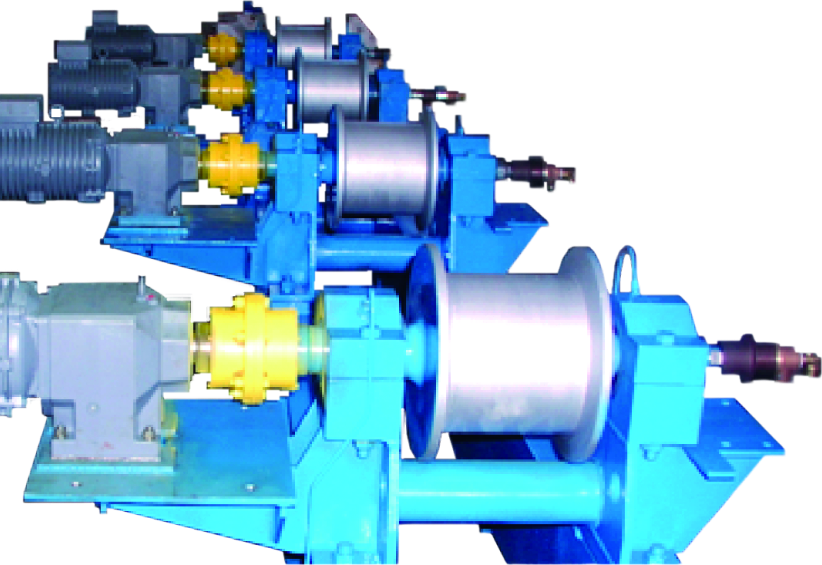

WELDED ROLLERS

Field of application:

Middle- and light-weight trailer tables for rolling mills.

Roller body material:

Carbon, structural and high-alloy steels.

Design features:

Roller necks heat treatment, internal cooling of roller body, static and dynamic balancing.

Dimensions:

Body diameter = 200 - 330 mm; body length = 800 - 6000 mm. Roller weight: up to 2,0 t.

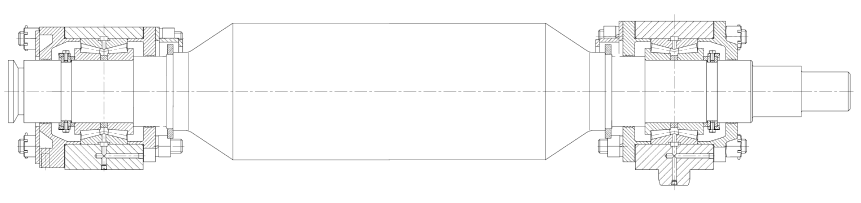

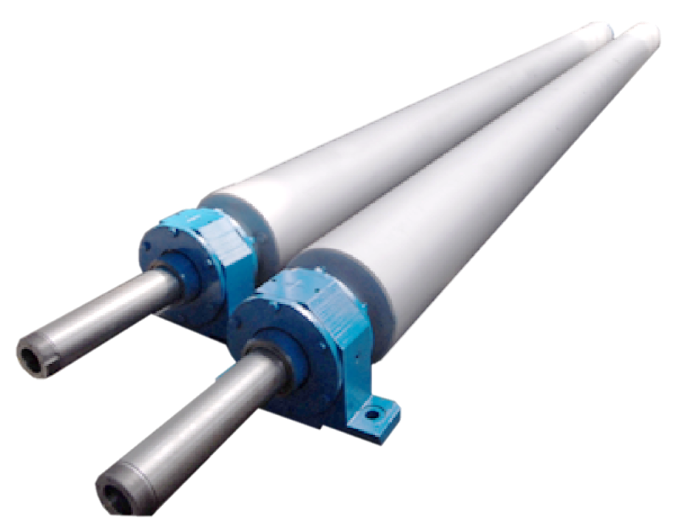

WELDED FURNACE ROLLERS

Field of application:

End-charged end-discharged furnaces.

Roller body material:

Heat- and wear-resistant steels and alloys.

Design features:

Body, shaft and journals internal cooling, thermal insulation.

Dimensions:

Body diameter = 260 - 365 mm; body length = 1200 - 4300 mm. Roller weight: up to 1,4 t.

Маса ролика: до 1,4 т

WORK AND BACKUP ROLLERS OF PLATE-STRAIGHTENING MACHINES AT IRON AND STEEL WORKS

Field of application:

In plate-straightening machines of hot and cold rolling mill lines, strip cutup and slitting units, sampling machines and etc.

Purpose:

Strip and plate straightening.

Design features:

Manufactured of low-alloy high-strength structural steel (forgings or round bars) with subsequent heat treatment and machining.

Roller outside diameter is from 50 to 430 mm, body length – up to 5000 mm.

Roller wear-resistance is ensured by high hardness of the working surface (55-65 HRC) obtained through various types of heat treatment (high-frequency current, industrial-frequency current, bulk hardening).

Advantages:

Up-to-date design of rollers, available materials and completing components used in the design, effective cooling of bearing supports and working zones of rollers when straightening hot rolled products, high guarantee obligations of the manufacturer, limited time of manufacture, optimum price.

ROLLERS OF SECTION AND PIPE-ROLLING MILLS STRAIGHTENING MACHINES

Field of application:

In straightening machines and presses of pipe-rolling and hot section mill lines.

Purpose:

Straightening of pipes and rolled section within the range of products of iron and steel works.

Design features:

Manufactured of tool and alloy high-strength steels (forgings or round bars) with subsequent heat treatment and machining.

Roller bodies are made with the preset shape (convex or concave), specified number and shape of passes, high accuracy and operating surface finish, wide range of diameters (up to 525 mm).

Roller wear resistance is provided due to high hardness of operating surface (55-65 HRC) obtained through different types of heat treatment (high-frequency current, industrial-frequency current, bulk hardening), surfacing, spraying with wear resistant materials and etc.

Advantages:

Up-to-date design of rollers, available materials and completing components, high guarantee obligations of the manufacturer, limited time of manufacture, optimum price.