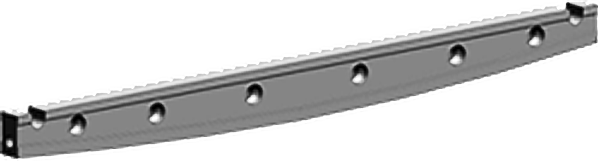

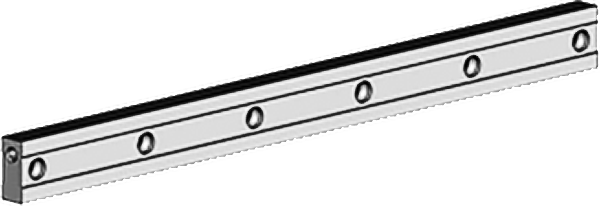

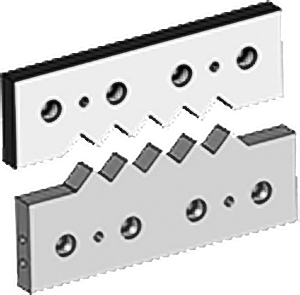

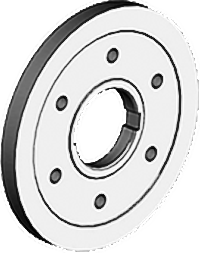

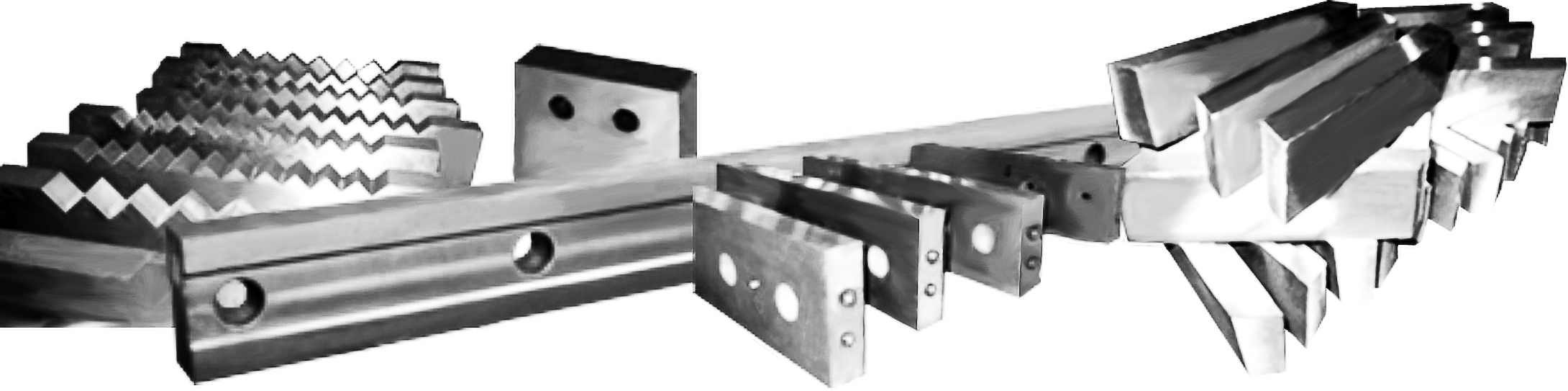

Blade material – high quality tool steel. In the process of steelmaking after-furnace ladle steel treatment and vacuum degassing are used that enable high purity of steel free from nonmetallic inclusions and homogeneity of chemical composition throughout the section.

Heat treatment is performed under conditions specifically developed in CNC equipment. As a result, the blade has the structure possessing optimum relationship of strength and viscosity properties that provides high resistance and long service life.

The blades are machined in machining centers that provide high accuracy of geometry.

Walkthroughs at all production stages guarantee high quality of blades and full conformity of their characteristics to their operation.

Investigations constant ly carried out at the premises of the works laboratory make it possible to improve continuously the blades production technique.