KNIVES

The material of the knives is high quality tool steel. In the process of steel smelting, ladle-furnace treatment and vacuum degassing are used, which allows to achieve high purity of steel from non-metallic inclusions and homogenous chemical composition over the entire cross section.

Heat treatment is carried out according to specially developed modes on CNC equipment. Thanks to this, the knife has a structure that has an optimal ratio of strength and viscous properties, which ensures high durability and long service life. Machining of knives is carried out at machining centers providing high accuracy of geometric dimensions. Walkthrough at all stages of production ensures high quality knives and full compliance of knive characteristics with the conditions of their operation. Constantly conducted research atb the plant laboratory allows us to continuously improve the knive manufacturing technology.

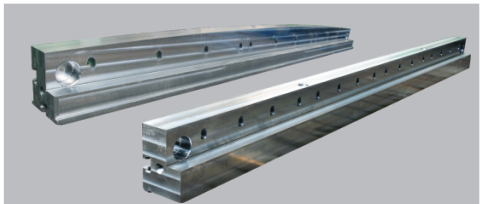

SHEAR CASSETTES (BASE BARS, CHOKS)

Application: cassettes provide reduction of specific loads during a cut from a knife to a support (bed), and also increase of the duration of operation of a support (bed) due to change of cassettes a knife seat is worn out.

SUPPORTS (SLIDERS, KNIVE FRAMES)

A support is a load-bearing part of shears on which the movable knife is mounted. Cutting is performed by support moving relative to the fixed knife.

Shear cassettes (base bars, choks)

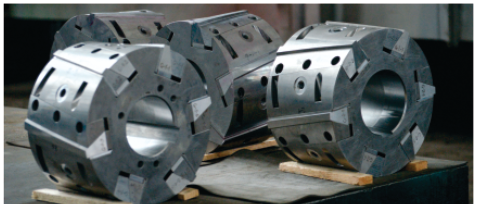

Drums for flyings drum-type shears

Scrap shear (chopper) drums

Shear cassettes (base bars, choks)