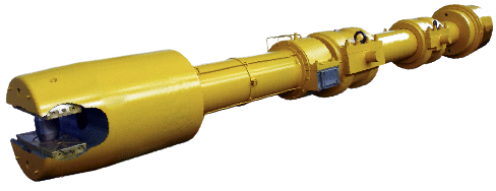

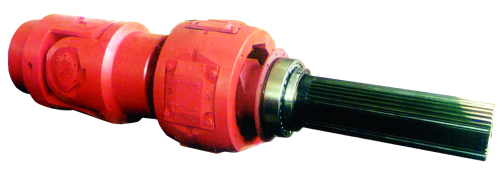

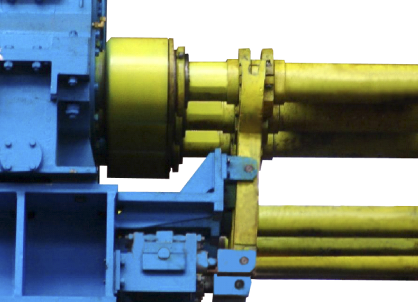

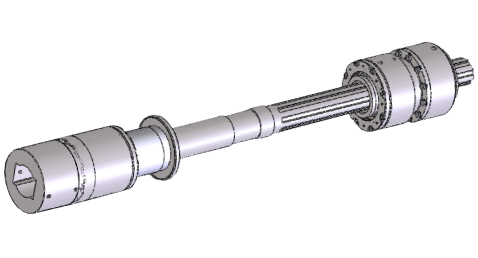

Field of application: Main drive lines of hot and cold rolling mills.

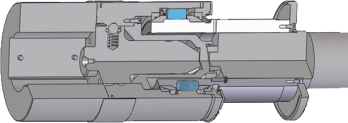

Designation: Torque transmission from electric motor to rolling mill stand work rolls.

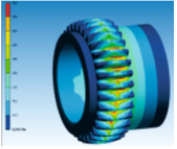

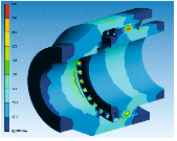

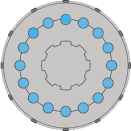

Design distinguishing features: Hinges and spindles are equipped with bronze plain bearing liners (plain plates) enabling spindle operation angles of 8°. Load-bearing parts of spindles are made of high-grade alloyed structural steel by forging with further heat-treatment and machining. Spindle head outer diameter: between 300 and 1600 mm. Spindle weight: up to 60 t. Transmitted torque: 13 00 TM. Provided rolling speed: up to 6 m/sec.

Advantages: Construction simplicity, maintainability, optimal price.