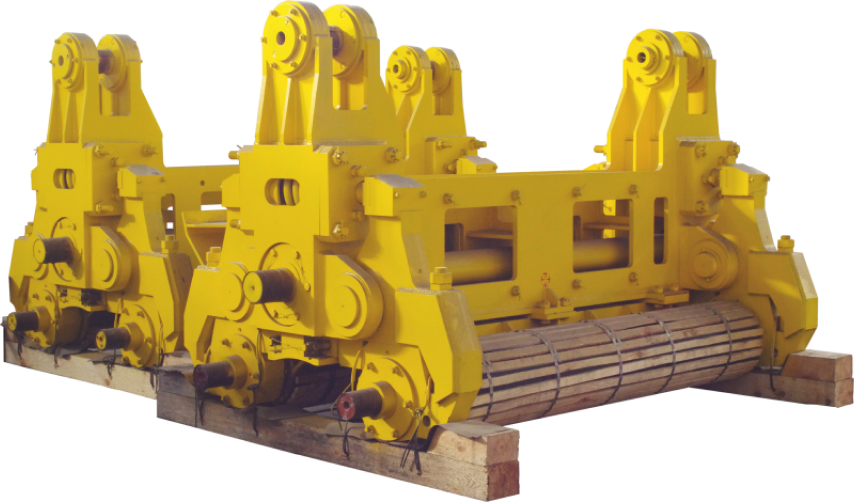

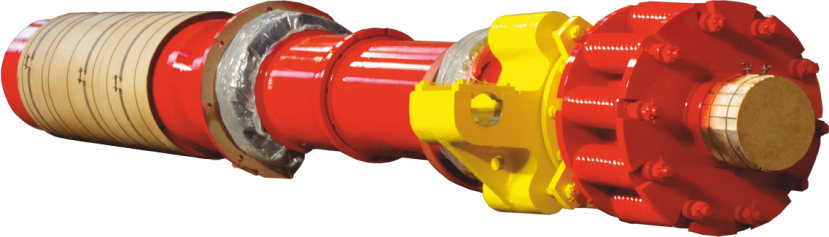

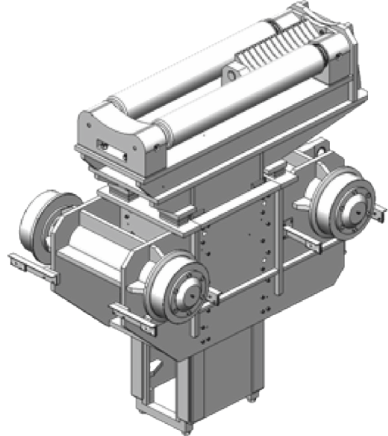

Application:

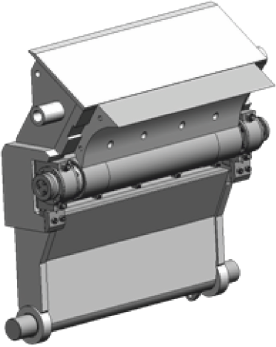

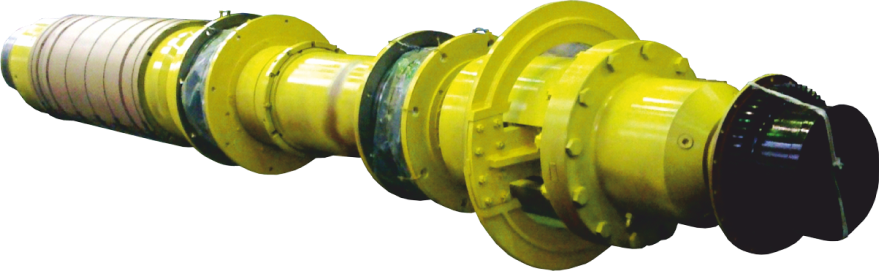

Cold strip mills, pickling, coating, cutting devices.

Function:

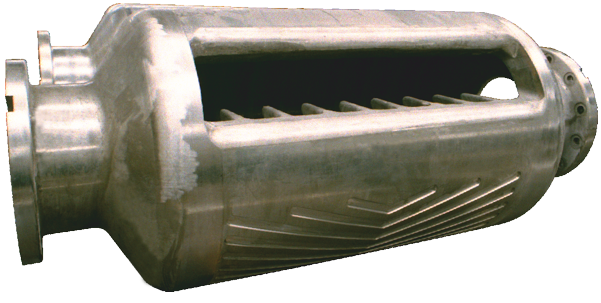

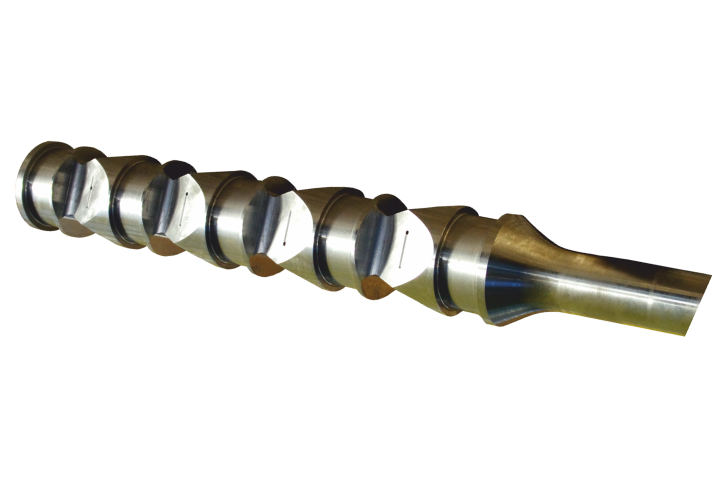

Coiling (uncoiling) of the finished strip into coil.

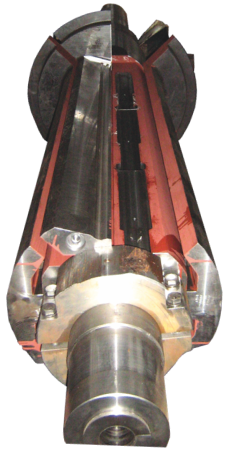

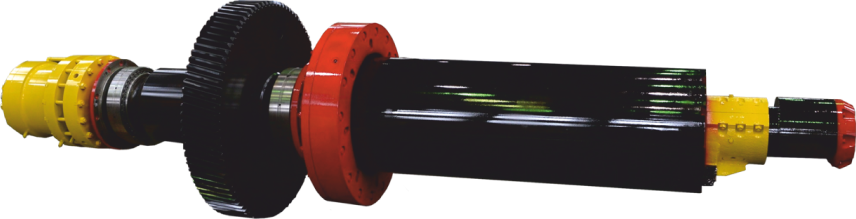

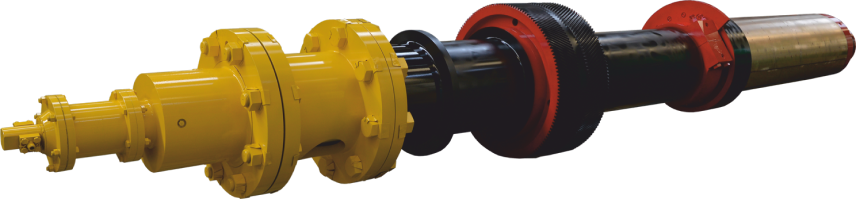

Special features:

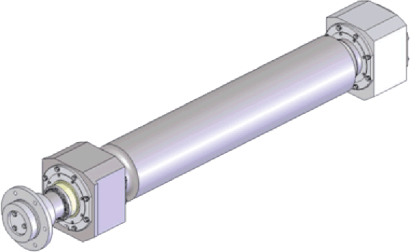

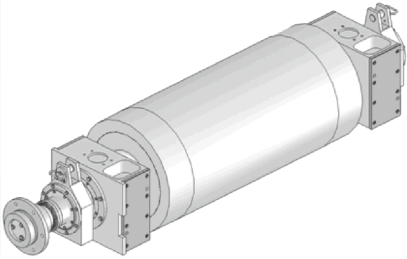

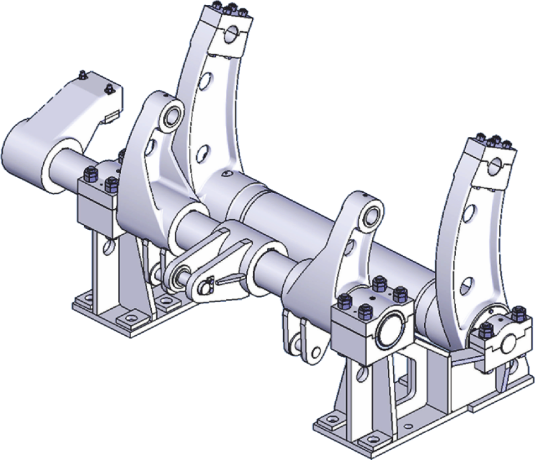

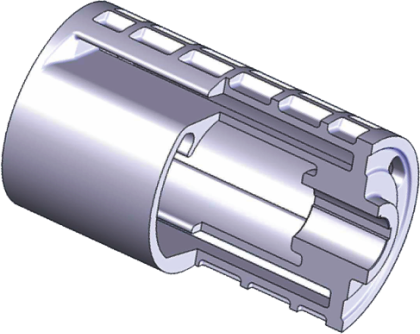

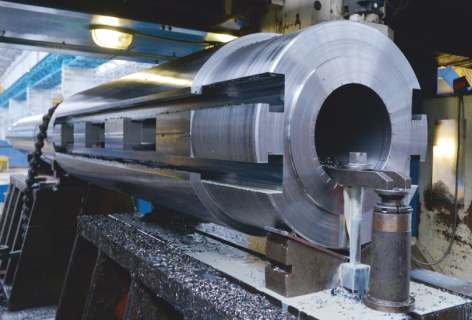

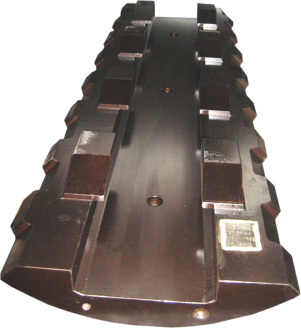

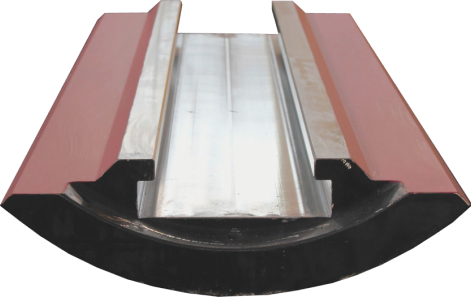

Load-bearing parts of reel block are made out of high quality alloyed steel by means of forging with subsequent heat treatment and machining. This design makes possible to change reel block without reducer dissassembling.

Advantages:

It can be produced for all cold rolling mills' line and relevant units.