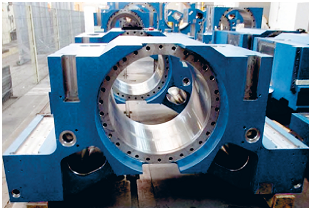

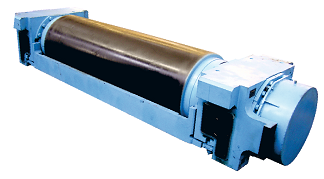

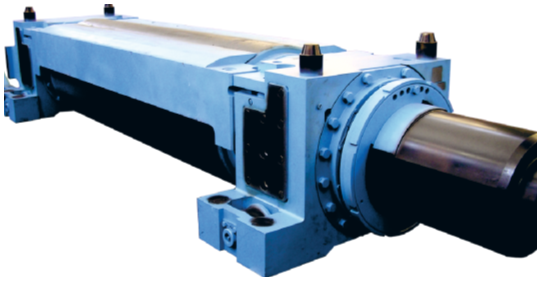

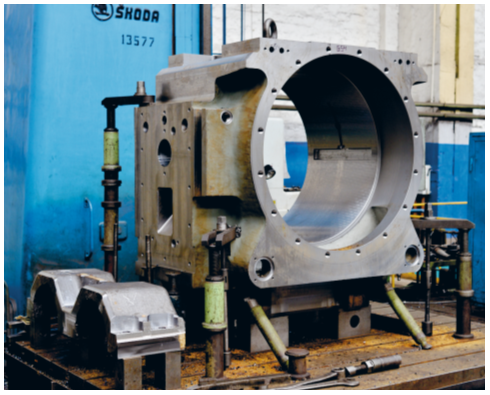

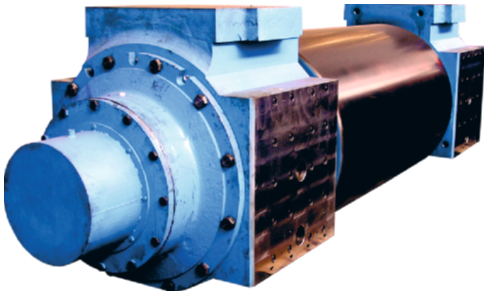

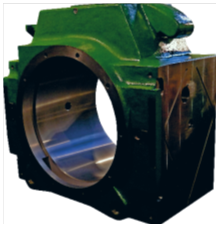

Field of application:

Cold and hot rolling mill stands.

Designation:

Basic parts in which bearing supports of work rolls lie.

Design distinguishing features:

Chocks have special holes for antifriction bearing and side support planes. To increase wear-resistance and to prolong chocks work duration these planes are equipped with lining plates having different hardness of surfaces: surface of plate adjacent to chock 180 HB, outer surface - 40...50 HRC. Chocks are made of castings (steel 35Л, 30ХГНМЛ, 35ХМЛ, 42CrMo4) and forgings (steel 45, 40Х). It's possible to make any grade of steel with a required chemical composition and mechanical properties at the Customer's request. Max. weight of 1 chock - up to 15 t.

Advantages:

Any required configuration, calculation of strength, optimization of design and weight by means of special computer programs, optimal price.