A blast furnace is an aggregate in which cast iron smelting is determined by the interaction of a column of charge materials moving from top to bottom and an gas counter flow stream.

The nature of the gases movement over the cross section of the furnace shaft depends on:

quality of charge materials;

distribution of charge materials on the top;

method of gas supply and removal.

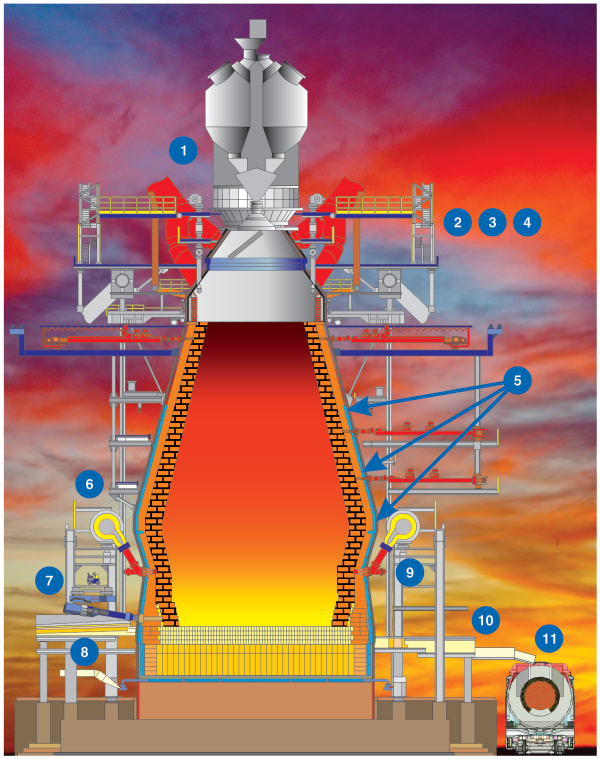

NKMZ PJSC produces a full list of equipment for the completion of a blast furnace, ensuring its operation, including:

1. Charging devices of:

trough-type;

bell-type.

2. Bleeder valves.

3.

Throttle valves.

4. Compensation valves.

5. Cooling plates.

6. Snort valves.

7. A set of equipment for servicing a cast iron taphole:

machines for taphole closing at blast furnace;

machines for taphole opening at blast furnace;

manipulators for casting trough covers;

pump-and-accumulator station of the casthouse.

8. Filters for water (including saltwater).

9.

Tuyere stock.

10. Oscillating troughs.

11. Mobile mixers.

12. Skips and skip hoists.